change cub cadet hg-72291 is a vital information for any house owner looking for to keep up their Cub Cadet tools. This complete walkthrough tackles the intricacies of this activity, from preliminary prognosis to last testing, making certain a easy and environment friendly substitute course of. A light mechanical coronary heart, as soon as vibrant with life, now requires tending. This information is designed to offer an in depth strategy to restoring it to its former glory.

This information particulars the steps wanted to diagnose and repair a malfunctioning HG-72291 half in your Cub Cadet, from figuring out the issue to sustaining the machine for future use. A cautious strategy is critical, as this half is important for the correct functioning of the machine. Carelessness can result in additional problems.

Figuring out the Downside

The Cub Cadet HG-72291 half, essential for the mower’s performance, can exhibit numerous points. Understanding these issues is vital to efficient troubleshooting and well timed repairs, stopping additional harm and dear replacements. Figuring out the foundation trigger is crucial to making sure a correct and long-lasting answer.Diagnosing the difficulty necessitates a scientific strategy. Failure to establish the precise downside precisely might result in pointless elements substitute, prolonging the restore course of and growing prices.

Frequent Points with the HG-72291 Half

The HG-72291 half, a significant element within the Cub Cadet mower’s operation, can expertise a number of malfunctions. These points can stem from numerous elements, together with regular put on and tear, improper upkeep, and, much less incessantly, manufacturing defects. Understanding the signs and causes is crucial for correct prognosis.

- Malfunctioning Blade Engagement Mechanism: A standard subject entails the blade engagement mechanism failing to securely lock the blades. This typically ends in the blades not participating correctly, hindering the mower’s reducing means. This may result in issue in beginning the mower, or in sure circumstances, the blade meeting utterly disengaging.

- Worn or Broken Transmission Elements: The HG-72291 element is incessantly related to the mower’s transmission system. Put on and tear on the transmission parts, reminiscent of gears, shafts, and bearings, can result in the HG-72291 exhibiting a grinding or dragging noise throughout operation. It is a signal of attainable harm to the interior parts.

- Insufficient Lubrication: Inadequate lubrication of the half, typically as a consequence of neglect of standard upkeep, can result in untimely put on and tear, impacting the element’s easy operation. This may manifest as sticking, seizing, or an uncommon noise. Improper lubrication practices may result in elevated friction, finally affecting the HG-72291’s efficiency.

- Manufacturing Defects: Although much less widespread, manufacturing defects may trigger points with the HG-72291 half. These defects could embrace flaws within the materials, improper meeting, or defective parts. Signs may embrace uncommon noises or a sudden failure of the half to operate accurately, even after routine upkeep.

Signs Indicating Alternative

Figuring out the signs that precede the necessity for changing the HG-72291 half is essential for well timed intervention. Ignoring these warning indicators can result in extra vital issues and doubtlessly expensive repairs.

- Uncommon Noises: A grinding, screeching, or dragging noise throughout operation might point out harm to the half’s inside parts or extreme put on. The precise sort of noise can present clues to the underlying downside.

- Problem in Beginning or Participating the Blades: If the blades fail to interact or the mower experiences issue beginning, the HG-72291 half is perhaps at fault. This might be an indication of a malfunctioning engagement mechanism or an issue inside the transmission system.

- Decreased Chopping Effectivity: Noticeable discount within the mower’s reducing effectivity is usually a symptom of points with the HG-72291. This might consequence from numerous issues, reminiscent of worn parts or a broken engagement mechanism.

- Seizing or Sticking: If the half experiences sticking or seizing, it signifies a big lubrication subject or a possible manufacturing defect. This typically results in issue in operation and may trigger additional harm.

Diagnosing the Downside, change cub cadet hg-72291

A scientific strategy is important to precisely diagnose the difficulty with the HG-72291 half. Ignoring the early signs can result in extra in depth and dear repairs.

- Visible Inspection: Fastidiously examine the half for any seen harm, put on, or particles. Search for indicators of cracks, breaks, or vital put on on transferring elements. This preliminary inspection can establish apparent issues.

- Useful Testing: Take a look at the half’s performance in a managed setting, simulating the situations underneath which it might function within the mower. This enables for commentary of the half’s efficiency and identification of any uncommon noises or difficulties.

- Seek the advice of the Handbook: Referencing the Cub Cadet proprietor’s handbook for troubleshooting steps may help establish potential causes and signs related to the HG-72291 element. The handbook supplies a complete information to troubleshooting.

- Skilled Evaluation (if essential): If the issue persists or can’t be recognized by way of the above steps, consulting a certified technician is really helpful. An expert evaluation can present a extra in-depth prognosis.

Gathering Essential Instruments and Supplies

Correct preparation is essential for a profitable Cub Cadet HG-72291 substitute. A well-stocked toolkit and the proper elements are important to keep away from expensive delays and potential security hazards. This part Artikels the important instruments and supplies wanted for the process, emphasizing security and the significance of high quality parts.

Important Instruments

A complete toolkit is important for the substitute course of. The next instruments are essential for disassembly, element removing, and reassembly. Correct dealing with and utilization of those instruments are important for a profitable and protected substitute.

- Sockets and Wrenches: Numerous sizes of sockets and wrenches are required for loosening and tightening bolts and nuts holding the previous element and attaching the brand new one. These instruments are important for disassembling and reassembling the elements, and the proper dimension is important to keep away from stripping bolts or damaging the element.

- Screwdrivers: Flathead and Phillips head screwdrivers are wanted for eradicating screws that safe numerous elements. Completely different sizes are essential for securing the substitute half accurately and making certain a comfortable match.

- Pliers: Needle-nose and slip-joint pliers are helpful for gripping and manipulating small elements through the course of. These are important for dealing with small elements, making certain appropriate alignment and stopping harm to parts.

- Hammer: A hammer, together with acceptable punches, is required for eradicating cussed parts. This instrument is important for breaking up parts or driving out pins if essential. Security glasses are completely required when utilizing a hammer.

- Torque Wrench: A torque wrench is essential for making certain correct tightening of fasteners. This instrument ensures the right amount of drive is utilized to stop harm to the element and keep the optimum efficiency of the substitute half.

- Drain Pan and Funnel: A drain pan and funnel are wanted for amassing any fluids that could be launched through the disassembly course of. These are essential for stopping spills and potential hazards.

- Work Gloves: Protecting work gloves are really helpful to stop damage or cuts through the course of. Defending palms from sharp edges and potential hazards is crucial.

- Security Glasses: Security glasses are a should to guard the eyes from particles or flying elements. That is important to stop eye accidents.

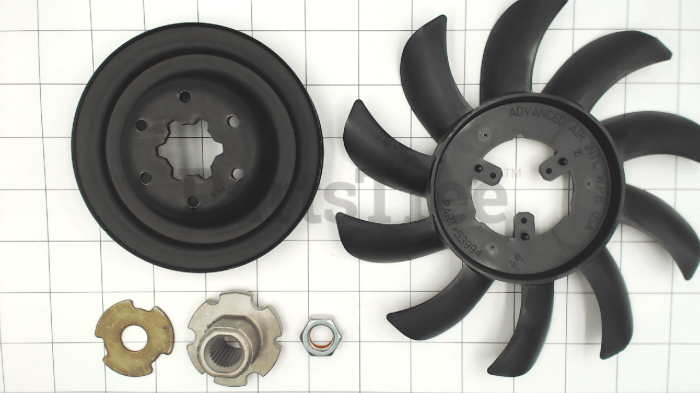

Alternative Components

A listing of attainable substitute elements is offered beneath. Selecting the proper elements is essential for the correct operate and longevity of the repaired tools.

- HG-72291 Element: The precise half quantity is crucial for making certain compatibility with the Cub Cadet mannequin. Make sure the half is accurately recognized to keep away from incompatibility points.

- Fasteners: Bolts, nuts, and screws may have substitute. These are important for securing the brand new element and making certain the tools’s integrity.

- O-rings and Seals: These parts may have substitute to make sure a correct seal and stop leaks. Their correct set up prevents leaks and ensures the tools’s efficiency.

Significance of Real or Equal High quality Components

Utilizing real elements or high-quality equivalents is essential for the long-term reliability and efficiency of the tools. Substituting with inferior parts can result in untimely failure and doubtlessly harmful conditions.

- Real Components: Real Cub Cadet elements are designed particularly for the machine, making certain optimum efficiency and compatibility. This ensures that the half meets the producer’s specs.

- Equal Components: Equal elements is usually a cost-effective different. Nevertheless, the standard of the equal half is important. All the time analysis the producer and make sure that the equal half meets the required specs.

Getting ready the Cub Cadet

Correct preparation is essential for a protected and profitable substitute of the Cub Cadet HG-72291 half. Ignoring these steps can result in harm, damage, and additional problems. Thorough preparation ensures the substitute course of proceeds easily and effectively, minimizing downtime and maximizing the probabilities of a profitable restore.Cautious disassembly and isolation of the defective element are paramount to keep away from pointless problems through the substitute process.

This meticulous strategy ensures that the substitute half is put in accurately and that the machine capabilities optimally after the restore. Following security protocols and securing the machine are equally necessary steps to stop accidents and guarantee a protected working setting.

Disassembling the Cub Cadet

Disassembling the Cub Cadet requires a scientific strategy to make sure that no elements are misplaced or broken through the course of. Begin by referring to the producer’s handbook for detailed directions particular to the mannequin. This doc will present exact steps for eradicating parts and securing them for protected storage. A well-organized workspace is important for environment friendly and protected disassembling.

Securing the Cub Cadet

Securing the Cub Cadet through the substitute course of is paramount to stop unintended motion and potential accidents. Inserting the machine on a secure, stage floor is step one. Use acceptable blocking or bracing strategies to stop the machine from tipping or shifting through the restore. This important precaution ensures a protected working setting and avoids surprising incidents.

Isolating the Defective Element

Figuring out the exact location of the defective HG-72291 element is important for a profitable substitute. Fastidiously look at the machine for any seen indicators of harm or put on on the affected space. Seek the advice of the producer’s troubleshooting information to know potential causes of the malfunction. This strategy will assist pinpoint the precise half needing substitute.

Security Measures

Adhering to security protocols is important throughout any restore course of. Disconnect the machine’s energy supply earlier than starting any disassembly. Guarantee all electrical connections are utterly disconnected to stop electrical shocks. Put on acceptable private protecting tools (PPE), reminiscent of security glasses, gloves, and durable footwear. These precautions will assist mitigate the chance of damage through the restore course of.

Securing the Machine Throughout Alternative

Correctly securing the Cub Cadet through the substitute course of is essential for the security of the technician and the prevention of harm to the machine. This step helps keep away from accidents through the work. Make the most of acceptable security tools reminiscent of jack stands or blocking supplies to make sure stability. Make sure the machine is firmly secured to stop any motion or shifting through the restore course of.

This technique prevents any unintended accidents or machine harm.

Changing the HG-72291 Half: How To Exchange Cub Cadet Hg-72291

The HG-72291 half, essential for the correct functioning of the Cub Cadet, typically requires substitute as a consequence of put on and tear or harm. This part particulars the step-by-step process for safely and successfully eradicating the previous half and putting in the brand new one, making certain optimum efficiency and longevity. Correct alignment and safe connections are paramount for profitable substitute.Changing the HG-72291 entails exact dealing with to keep away from harm to the encircling parts.

Following the detailed directions beneath will reduce the chance of problems and guarantee a easy substitute course of. Cautious consideration to element all through the method is important for a profitable final result.

Eradicating the Previous HG-72291 Half

Cautious removing of the previous HG-72291 half is crucial to stop harm to the encircling parts. This course of entails methodical disassembly to keep away from potential problems. The steps beneath Artikel the method.

- Find the HG-72291 half. Make sure the machine is securely supported and the world is well-lit. Use acceptable security precautions, reminiscent of carrying security glasses and gloves.

- Disconnect any electrical connections or hoses connected to the half. Doc the disconnections for correct reassembly.

- Use the suitable instruments to fastidiously loosen and take away any fasteners securing the half. Notice the precise sort and torque specs of fasteners for proper reassembly.

- Gently pry or carry the half away from its mounting factors, taking care to not harm adjoining parts. Pay shut consideration to any clips or retaining mechanisms.

- Examine the previous half for any seen harm or put on that may point out further points. Doc any findings for future reference.

Putting in the New HG-72291 Half

Right set up of the brand new HG-72291 half is essential for optimum efficiency and stopping future points. Exact alignment and safe connections are very important to make sure easy operation.

- Fastidiously align the brand new HG-72291 half with its mounting factors. Confirm the half matches snugly and aligns correctly with present parts.

- Apply the suitable fasteners, making certain they’re accurately tightened to the producer’s specs. Use a torque wrench to realize exact tightening.

- Reconnect any electrical connections or hoses, making certain they’re securely related and correctly oriented.

- Completely examine the brand new half for correct operate. Function the machine in a managed setting to confirm the half’s performance.

- Carry out a last inspection of all connections and fasteners to make sure the whole lot is safe and accurately put in. This can assist forestall any points sooner or later.

Particular Strategies and Concerns

Sure strategies and concerns can streamline the substitute course of and stop potential problems. Understanding these elements will enhance the general expertise.

- Utilizing a torque wrench is crucial for making certain the proper tightness of fasteners. Incorrect torque can result in loosening or harm.

- Correct lubrication of transferring elements can enhance efficiency and longevity. Seek the advice of the machine’s handbook for really helpful lubricants.

- Documenting the disassembly course of with images or detailed notes is extremely really helpful. This may help with reassembly and troubleshooting if points come up.

- If any uncommon resistance or issue is encountered, seek the advice of the machine’s handbook or search skilled help. This helps forestall additional harm.

Potential Challenges and Options

Troubleshooting potential points through the substitute course of can guarantee a easy transition. Addressing these challenges successfully can save time and sources.

- A stripped screw or fastener can happen if the torque is just too excessive. Use a smaller screwdriver or a specialised instrument for exact removing and reinstallation. Exchange broken screws or fasteners instantly.

- Misaligned parts may cause improper functioning. Fastidiously align the half with its mounting factors and use shims or spacers if essential. Use acceptable measuring instruments to make sure correct alignment.

- Incorrect connections {of electrical} parts or hoses can result in malfunctions. Double-check all connections and guarantee correct orientation. Seek the advice of the machine’s wiring diagram if wanted.

Step-by-Step Process Desk

| Step | Description | Visible Support |

|---|---|---|

| 1 | Find the HG-72291 half | [Diagram showing the location of the HG-72291 part] |

| 2 | Disconnect any electrical connections | [Diagram illustrating disconnection of electrical connections] |

| 3 | Loosen and take away fasteners | [Diagram showcasing fastener removal] |

| 4 | Gently take away the previous half | [Diagram demonstrating removal of the old part] |

| 5 | Align and set up the brand new half | [Diagram depicting proper alignment of the new part] |

Ending Up the Alternative

Finishing the Cub Cadet HG-72291 substitute entails meticulous reassembly and thorough checks to make sure correct operation. This important step ensures the restored performance of the machine and prevents potential future points. Correct reassembly is crucial for the long-term reliability and efficiency of the tools.Cautious consideration to element throughout reassembly is paramount. Every element should be secured accurately, and all connections verified to keep away from any potential malfunctions.

Testing procedures, detailed beneath, will verify that the substitute half capabilities seamlessly inside the Cub Cadet’s system.

Reassembly Procedures

Right reassembly of the Cub Cadet is important to restoring its operational effectivity. Fastidiously comply with the producer’s service handbook for step-by-step directions particular to your mannequin. Incorrect reassembly can result in element harm, lack of operate, and even security hazards. Adhere to the producer’s pointers for torque specs and fastener sorts.

Connection Verification

Thorough inspection of all connections is crucial. Confirm that each one wires, hoses, and belts are accurately related and securely mounted. Free connections can result in efficiency points and even electrical hazards. Visible inspection and bodily testing must be performed to make sure that all connections are tight and practical.

Testing the Changed Half

Testing the newly put in HG-72291 half is important to substantiate its correct operation. Begin by operating the engine at idle velocity for a couple of minutes to make sure easy operation. Then, enhance the engine velocity to examine for any uncommon noises or vibrations. Pay attention for any uncommon noises, and observe for any indicators of overheating. Correct functioning must be evident with none surprising sounds or erratic conduct.

Useful Verification

Confirming the meant performance of the changed half entails sensible testing. Execute the duties for which the half is accountable to confirm its correct operation. If the half is a part of a mowing system, take a look at the reducing operate and guarantee easy operation. Whether it is a part of a hydraulic system, function the system to substantiate correct fluid circulation.

The half ought to operate as meant, with none uncommon delays or errors.

Troubleshooting Frequent Points

Publish-replacement upkeep is essential for making certain the HG-72291 half capabilities optimally and extends the lifetime of the Cub Cadet. Correct prognosis and backbone of potential points can forestall additional problems and dear repairs. Addressing these points proactively may save effort and time in comparison with coping with escalated issues down the road.Troubleshooting entails figuring out, diagnosing, and resolving points which will come up after changing the HG-72291 half.

This course of consists of understanding the attainable causes of issues, systematically checking for faults, and implementing efficient options to revive the machine’s performance.

Potential Issues and Options

Correctly figuring out and diagnosing points after changing the HG-72291 element is crucial for efficient troubleshooting. A scientific strategy is vital to pinpoint the foundation explanation for any malfunction. This methodical course of will forestall pointless harm and result in a faster decision.

| Potential Downside | Attainable Trigger | Troubleshooting Steps | Options |

|---|---|---|---|

| Machine Fails to Begin | Defective connections, low gas, air leaks, or a clogged gas filter. | 1. Test all connections for tightness and corrosion. 2. Confirm gas stage and make sure the gas system is functioning accurately. 3. Examine for air leaks across the gas strains and carburetor. 4. Test the gas filter for blockages. | Tighten free connections, add gas, restore or change gas strains, and change the gas filter if clogged. |

| Uneven Chopping or Poor Chopping Efficiency | Incorrect blade alignment, uninteresting blades, or a misadjusted deck peak. | 1. Confirm the blade alignment utilizing a straight edge. 2. Test the blade sharpness and change if uninteresting. 3. Alter the deck peak to the really helpful stage for the specified lower. | Reallign the blades if essential, sharpen or change the blades, and alter the deck peak based on the producer’s specs. |

| Extreme Vibration | Free or broken parts, unbalanced blades, or misaligned elements. | 1. Examine all bolts and fasteners for tightness. 2. Test the blade steadiness utilizing a balancer. 3. Examine the mower deck for any misalignments. | Tighten free parts, steadiness the blades, and proper any misalignments. |

| Uncommon Noises | Worn or broken parts, free belts, or friction between transferring elements. | 1. Establish the supply of the noise by fastidiously listening to totally different working elements. 2. Examine belts for put on and tear and change if essential. 3. Look at all transferring parts for extreme play or harm. | Lubricate transferring elements, change worn belts, and restore or change broken parts. |

| Hydrostatic Drive Points (if relevant) | Low fluid ranges, leaks, or a malfunctioning pump. | 1. Test the hydrostatic fluid ranges. 2. Examine for leaks within the hydraulic system. 3. Examine the pump for correct functioning. | Prime up the fluid if low, restore or change any leaks, and contemplate skilled service if the pump is malfunctioning. |

Significance of Lubrication

Common lubrication is important for easy operation and extended lifespan of the Cub Cadet’s mechanical parts. Lubrication helps cut back friction, stopping put on and tear, and ensures correct operate of the transferring elements. This proactive upkeep technique prevents potential breakdowns and dear repairs.

- Correct lubrication of transferring elements reminiscent of gears, shafts, and bearings is essential for minimizing friction and maximizing the machine’s longevity.

- Use the proper sort of lubricant specified within the proprietor’s handbook to keep away from damaging the machine.

- Common lubrication intervals, as really helpful within the proprietor’s handbook, must be adhered to for optimum efficiency.

Adjustment Procedures

Right changes are important for making certain optimum efficiency and stopping additional points. Changes like deck peak, blade alignment, and hydrostatic drive settings must be carried out as per the producer’s pointers. These procedures are essential for protected operation and maximizing the effectivity of the machine.

- Consult with the proprietor’s handbook for particular directions and really helpful changes for the Cub Cadet mannequin.

- Changes must be carried out cautiously, following all security precautions Artikeld within the handbook.

- Correctly calibrated settings contribute to environment friendly reducing and general machine efficiency.

Sustaining the Cub Cadet

Correct upkeep of your Cub Cadet, significantly the HG-72291 half, is essential for making certain its longevity and optimum efficiency. Neglecting routine checks can result in untimely put on and tear, growing the chance of expensive repairs and doubtlessly compromising security. This part Artikels preventative measures and upkeep schedules to maximise the lifespan of your machine and keep away from future points.

Preventive Upkeep Procedures

Common inspections and maintenance are important to stop potential issues with the HG-72991 half and the general machine. These proactive steps can establish minor points earlier than they escalate into vital breakdowns. Routine upkeep additionally helps make sure the half operates at peak effectivity.

- Common Cleansing: Thorough cleansing of the HG-72991 half and the encircling space is important. Take away particles, grass clippings, and dust to stop clogging and untimely put on. This consists of cleansing the air consumption and exhaust programs.

- Lubrication: Common lubrication of transferring elements, together with these inside the HG-72991 meeting, is important. Comply with the producer’s suggestions for lubrication frequency and sort of lubricant. Correct lubrication reduces friction, extends element life, and minimizes put on.

- Inspection for Harm: Visually examine the HG-72991 half for any indicators of harm, reminiscent of cracks, bends, or free connections. Early detection of those points permits for immediate repairs and prevents additional harm. Search for any indicators of rust or corrosion as properly.

Upkeep Frequency

Adhering to a constant upkeep schedule is vital to stopping points and lengthening the lifespan of the HG-72991 half and the complete Cub Cadet. The frequency of checks will differ relying on utilization.

| Utilization Frequency | Frequency of Upkeep Checks |

|---|---|

| Gentle use (e.g., occasional yard work) | Weekly |

| Reasonable use (e.g., weekly yard upkeep) | Bi-weekly |

| Heavy use (e.g., each day yard work, landscaping) | Weekly or extra, relying on particular situations |

Common upkeep, carried out as scheduled, can prolong the lifespan of the HG-72991 half by considerably lowering the chance of untimely put on and tear, in addition to making certain the Cub Cadet stays dependable and practical.

Suggestions for Extending Lifespan

A number of suggestions can contribute to the long-term reliability of your Cub Cadet and the HG-72991 half.

- Correct Storage: Retailer the Cub Cadet in a clear, dry location when not in use. This helps forestall rust and corrosion, defending the HG-72991 half and different parts.

- High quality Gas: Utilizing high-quality gas, free from contaminants, is crucial for the machine’s general efficiency and the longevity of the HG-72991 half. Utilizing gas stabilizers during times of non-use additional extends its lifespan.

- Following Working Tips: Adherence to the producer’s working pointers ensures that the machine is used inside its design parameters. This safeguards the HG-72991 half and different important parts from undue stress.

Common Upkeep Guidelines

This guidelines supplies a structured strategy to making sure common upkeep.

- Weekly: Clear the HG-72991 half, examine for harm, and lubricate transferring elements.

- Bi-weekly/Month-to-month: Examine the complete machine for put on and tear, and examine fluid ranges (oil, gas).

- Quarterly/Seasonally: Thorough cleansing of the machine, changing air filters, and checking belt stress.

Final Phrase

In conclusion, changing the Cub Cadet HG-72291 half, although seemingly advanced, is achievable with meticulous consideration to element. This information supplies a complete roadmap, from preliminary prognosis to last testing, making certain a profitable final result. With correct care and a spotlight, you may restore your Cub Cadet to optimum working situation. Might your machine serve you faithfully for years to come back.

Important Questionnaire

What are widespread signs that point out the necessity to change the HG-72291 half?

Frequent signs embrace uncommon noises, lowered efficiency, or full failure of the element’s operate. Seek the advice of the machine’s handbook for particular signs referring to the HG-72291 half.

What security precautions must be taken when engaged on the Cub Cadet?

All the time disconnect the ability supply, put on acceptable security gear (eye safety, gloves, and so forth.), and safe the machine to stop unintended motion. Correct security protocols are paramount on this course of.

What are some widespread points which will come up after the substitute?

Misalignment, improper connections, and insufficient lubrication are potential points. Troubleshooting entails checking connections, adjusting parts, and re-lubricating transferring elements as essential.

How incessantly ought to preventive upkeep be carried out on the HG-72291 half and the machine?

Common upkeep, together with lubrication and visible inspection, is really helpful to stop future points. Consult with the Cub Cadet handbook for particular suggestions.